A unipolar rotary vane vacuum pump is a vacuum device widely used in industry and laboratories. Its main function is to extract gases by means of rotating vanes, thus creating a vacuum environment.

1.Working principle

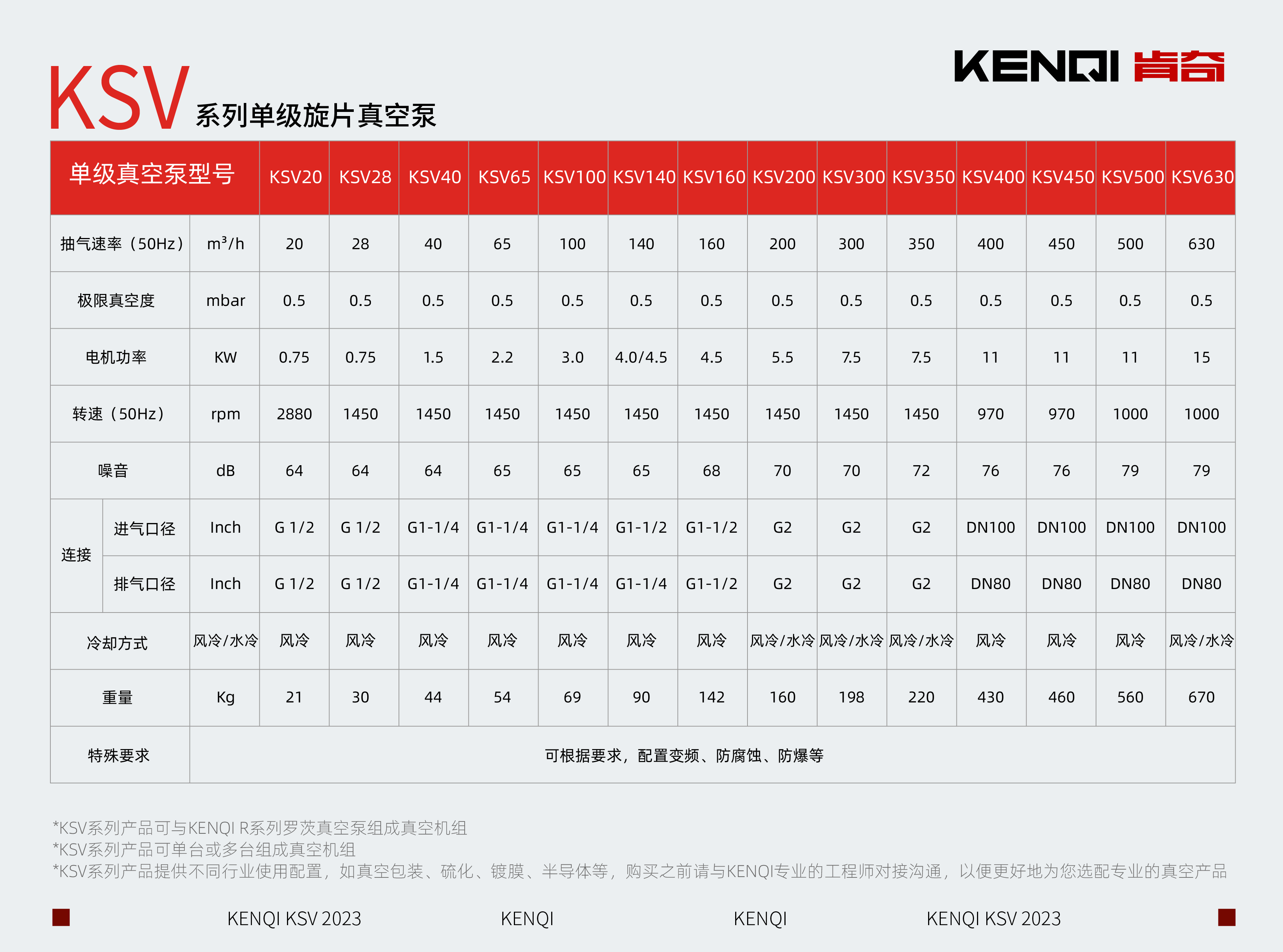

The working principle of unipolar rotary vane vacuum pump is based on the rotary movement of the rotary vane. When the motor drives the rotary vane to rotate, gas is sucked into the pump body, and the movement of the rotary vane causes the gas to be compressed and discharged, thus creating a low-pressure environment in the pump body. The pumps can operate effectively in a pressure range from 1000 mbar to 0.08 mbar and are suitable for a wide range of applications such as food packaging, metal processing and the petrochemical industry.

2. Areas of application

Monopole rotary vane vacuum pumps are widely used in the following areas due to their high efficiency and reliability:

Food packaging: for extending the freshness of food products, preventing oxidation and bacterial growth.

Metal industry: to provide the necessary vacuum environment during heat treatment and coating of metals.

Petrochemical industry: for vacuum extraction during chemical reactions and evaporation of substances.

Laboratory: to provide the required vacuum conditions in scientific experiments to ensure the accuracy and reliability of the experiments.

3.Maintenance and upkeep

In order to ensure the normal operation and prolong the service life of oil and gas separation single-stage rotary vane vacuum pump, regular maintenance and repair are required. Specifically include:

Check the oil level: check the oil level in the pump body regularly to ensure that the oil level is within the prescribed range. If the oil level is too low, the suitable vacuum pump oil should be supplemented in time.

Replace the oil seal: if the oil seal is found to be leaking or badly worn, it should be replaced with a new one in time.

Clean the pump body: clean the inside of the pump body regularly to remove accumulated dirt and impurities.

Check the exhaust filter: regularly check the clogging of the exhaust filter, if the clogging is serious, it should be replaced with a new filter in time.

Keep the pump body clean: keep the outside of the pump body clean and dry to prevent dust and moisture from entering the inside of the pump body.