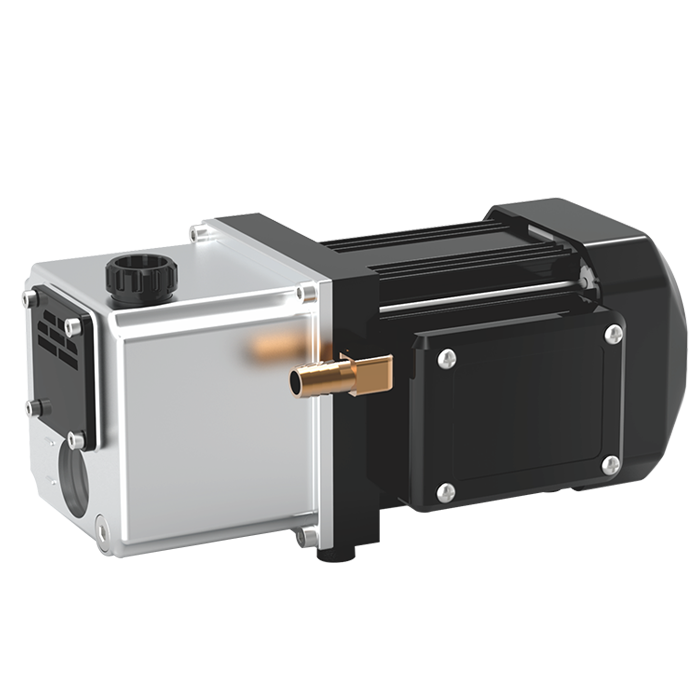

A monoblock is an engine component designed for long-term operation with high strength and durability. Its design often includes optimized cylinder block construction to ensure reliability and performance under high pressure and temperature conditions.

Integral Cylinder Block Long Term Operation Industrial Pump

1.Structural Advantages of Integral Cylinder Block

Compact structure, good rigidity: Integral cylinder block industrial pump is made of high-strength materials, characterized by compact structure and good rigidity. This design can withstand large mechanical and thermal loads, ensuring the stability and reliability of the pump during long-term operation.

Excellent heat dissipation performance: Integral cylinder block industrial pumpand the cylinder block adopt good heat dissipation design, which can quickly conduct the heat generated by combustion or friction out to ensure that the pump can run stably even in a high temperature environment.

Corrosion and abrasion resistance: modern industrial pump is usually made of corrosion-resistant materials to improve the service life of the pump. At the same time, the surface of the cylinder body has been specially treated with excellent wear resistance, reducing the performance degradation and maintenance costs due to wear and tear.

2.the performance characteristics of industrial pumps

High efficiency and energy saving: the industrial pump adopts advanced hydrodynamic design and manufacturing process, which is characterized by high efficiency and energy saving. With the same flow rate and head, industrial pumps consume less energy, which helps reduce production costs.

Stable and reliable: the structure of the industrial pump is reasonably designed, and the moving parts are precisely processed and strictly tested to ensure the stability and reliability of the pump during long-term operation. At the same time, the pump body is equipped with various protection devices, such as overload protection, overheating protection, etc., to cope with possible abnormalities.

Strong adaptability: industrial pumps are suitable for a variety of media and working conditions, such as clear water, sewage, corrosive liquids and so on. Users can choose the appropriate pump type and configuration according to the actual demand to meet different production needs.

3. long-term operation considerations

Maintenance: In order to ensure the stability and reliability of the overall cylinder long-term operation of industrial pumps, users should regularly maintain the pump. This includes checking the wear and tear of the pump, replacing worn parts, cleaning the pump body, etc..

Lubrication and cooling: Integral cylinder long-term operation of industrial pumps need good lubrication and cooling system to maintain its efficient operation. Users should regularly check the quality and quantity of lubricant, and replace or replenish the lubricant in time; at the same time, ensure the normal operation of the cooling system to avoid damage to the pump due to overheating.

Monitoring and testing: Users should install appropriate monitoring and testing equipment to monitor the pump's operating status in real time, such as vibration, noise, temperature, etc.. Once abnormalities are found, the pump should be shut down immediately for inspection and troubleshooting.