A suction port connection threaded vacuum pump is a device used to pump gases or liquids, and its design often includes specific connection threads for attachment to other equipment or piping systems. Here are some key points about suction port connection threaded vacuum pumps.

Suction Port Connection Threaded Vacuum Pump

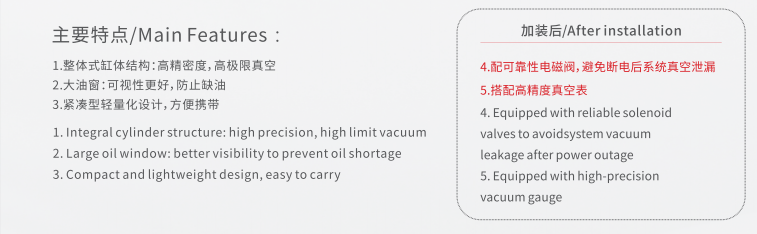

1. Connection threads of the suction port

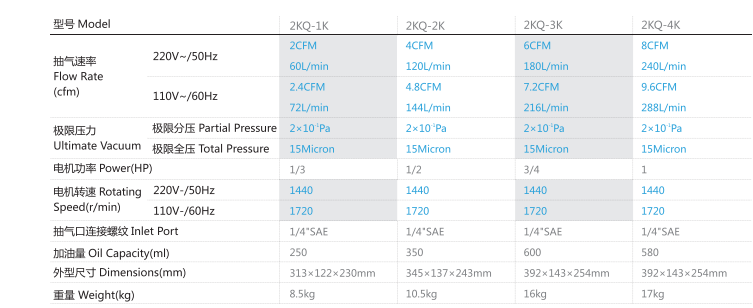

The connection threads of the suction port are usually made in inch or metric standard, and common sizes include 1/4“ and 3/8”. These threads ensure that the vacuum pump is connected to piping or other equipment in a sealed manner to prevent gas leakage.

2. Types of vacuum pumps

There are several types of vacuum pumps, including miniature vacuum pumps and diaphragm pumps. Miniature vacuum pumps are usually small in size, suitable for portable applications, and able to switch between pumping and priming.

3. Areas of application

Vacuum pumps with threaded suction port connections are widely used in refrigeration, chemical and laboratory applications. In refrigeration systems, vacuum pumps are used to extract air and moisture from the system to ensure efficient operation. In laboratories, vacuum pumps are used for sample extraction and processing to ensure the stability of the experimental environment.

4. Connection and Installation

When installing a vacuum pump, it is vital to ensure that the connection threads of the suction port match the piping system. The use of suitable sealing materials (e.g. Teflon tape) can effectively prevent leakage and ensure a tight and safe system. In addition, choosing the right adapters can also help to make connections between different sizes.

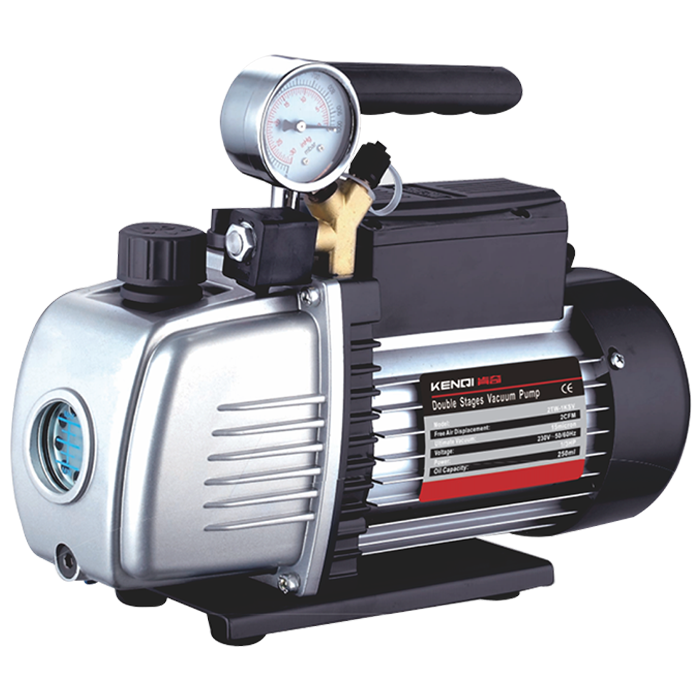

5.Appearance

On the pump body, you can also see a number of knobs and switches, which are carefully arranged in easy-to-reach positions to facilitate the user's adjustment of various parameters and control of the equipment. In addition, the pump body is also equipped with a number of indicator lights and pressure gauges, which can display the working status and performance parameters of the equipment in real time, helping users to better monitor and manage the operation of the vacuum pump.