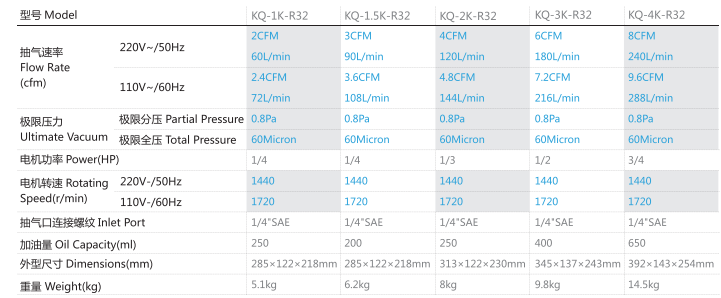

Ultimate partial pressure and ultimate full pressure are two important parameters when selecting a new refrigerant vacuum pump. Vacuum pumps with an ultimate partial pressure of 0.8 Pa and an ultimate full pressure of 60 Micron are typically used in applications requiring high vacuum levels.

Partial Pressure 0.8Pa Total Pressure 60Micron New Refrigerant Vacuum Pump

1.Principle of operation

The operating principle of new refrigerant vacuum pumps usually involves a combination of technologies such as electric pumps, compressors and cold baths. By circulating the refrigerant through the compressor and pumping and compressing the gas by the vacuum pump, the system can achieve the required vacuum level. At the same time, new refrigerant vacuum pumps also use advanced sealing technology and materials to ensure that there is no leakage of refrigerant during the pumping process.

2.Application Scenarios

The new refrigerant vacuum pump has a wide range of applications in many fields, including but not limited to:

Refrigeration and air-conditioning industry: it is used for vacuuming, charging refrigerant and recovering refrigerant in refrigeration and air-conditioning systems. Its fast, safe and efficient performance is widely recognized.

Optical electronics industry: in high-precision manufacturing industries such as optoelectronic materials, semiconductor materials, electronic materials, etc., the new refrigerant vacuum pump's advantages of high vacuum, stability and high flow rate satisfy the strict requirements for vacuum pumps in these industries.

Medical industry: in medical equipment, such as oxygen, sputum, infusion and other links, the new refrigerant vacuum pump can effectively ensure the safety and hygiene of medical equipment.

Experimental research: in the laboratory vacuum test, chemical reaction, physical experiments, etc., the new refrigerant vacuum pump's high precision, high flow, low noise, anti-corrosion and other characteristics provide an important guarantee for experimental research.

3.Product features

High efficiency and energy saving: the new refrigerant vacuum pump adopts advanced compression technology and materials with higher energy efficiency ratio, which can significantly reduce energy consumption.

Environmental protection and safety: using new refrigerants, such as R32, R290, etc., which have lower global warming potential and ozone depletion potential, which is conducive to environmental protection. At the same time, new refrigerant vacuum pumps also focus on safety performance during the design and manufacturing process to ensure safety during use.

Intelligent control: Many new refrigerant vacuum pumps are equipped with intelligent control systems, which can monitor and adjust the working status of the pumps in real time and improve the stability and reliability of the equipment.

Easy to maintain: the structure of new refrigerant vacuum pumps is reasonably designed, easy to disassemble and clean, reducing the maintenance cost and time.