How to reduce noise during the production of rotary vane vacuum pumps

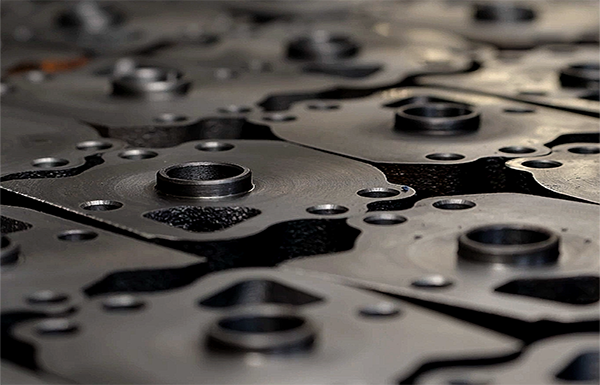

1. Impact of the rotary vane on the cylinder wall

If the design, manufacture or material is not appropriate, caused by the sliding of the rotor blade, or due to the existence of exhaust dead space, incompressible oil caused by the head of the rotor blade can not always close to the cylinder wall operation, will cause the rotor blade on the cylinder wall of the impact of the sound. Therefore, it is preferable to use the structure of a garden arc to separate the intake and exhaust ports. Eliminate the dead space with the exhaust guide groove. In the use of line separation structure, should try to shorten the distance from the exhaust end point to the cut point, for 70l/s rotary vane pump, considering the actual thickness of the rotary vane, it is recommended to take 7 ~ lomm, large pumps to take a large value. Too close, due to the rotor

Too close, due to the existence of the rotor vane groove and the head of the rotor vane only a narrow band contact, the rotor vane turned to the cut point position when the sealing effect is not good, it will affect the pumping speed and even the ultimate pressure. It can be seen that this structure can not completely eliminate the exhaust dead space, limiting the level of noise reduction.

Rotor, cylinder wall impact sound.

The size and location of the two volumes are related to the noise.

2.Valve piece on the valve seat and support the impact of noise

Inhaled gas volume is large, the pump circulating oil volume is more, the greater the valve noise, the valve jumps high, the valve area is large, the valve noise is also large, the valve material also has a certain impact. Rubber valve sheet noise should be better than steel or laminate. For this reason, the amount of oil inlet should be restrained, the valve plate should be closed in time, to be tight. Pay attention to the selection of materials and structure of the valve.

3.the box echo and bubble rupture sound gas volume increases, this noise will increase. Therefore, open the gas town or through the atmosphere when the noise will increase significantly. If the volume of gas ballast is adjustable, the volume of gas ballast can be reasonably adjusted.

4,.a large amount of gas and oil discharged when the impact of oil baffle plate and other parts of the noise. If the rigidity of the parts is not enough, or not fastened, resulting in vibration and collision, will make the noise increase. Therefore, the oil baffle plate should not only have enough rigidity and fastening, but also, in the need to contact with other parts (such as oil tanks), the use of rubber folder method can avoid vibration-induced collision noise, and improve the effect of oil blocking.